Where are shut off valves cdl – Where are shut-off valves in CDLs? This is a question that many drivers ask, and it’s an important one to know the answer to. Shut-off valves are essential for isolating and repairing sections of a CDL’s fuel system, and they can also be used to prevent fuel leaks in the event of an accident.

In this article, we’ll discuss the different types of shut-off valves used in CDLs, where they’re typically located, and how to operate them safely.

Shut-Off Valve Locations: Where Are Shut Off Valves Cdl

Shut-off valves are crucial components in commercial driver’s license (CDL) vehicles, enabling drivers to quickly isolate fuel or air supply in case of emergencies or maintenance needs. These valves are typically located in specific areas of the vehicle, ensuring easy accessibility and efficient operation.

To enhance clarity, we have compiled a comprehensive list of typical shut-off valve locations along with corresponding diagrams or illustrations:

Fuel Shut-Off Valves

- Fuel Tank:Located near the fuel tank, typically on the side or underneath.

- Engine Compartment:Situated close to the engine, often near the fuel filter or fuel lines.

- Cab:Accessible from inside the driver’s cab, usually under the dashboard or near the steering column.

Air Shut-Off Valves

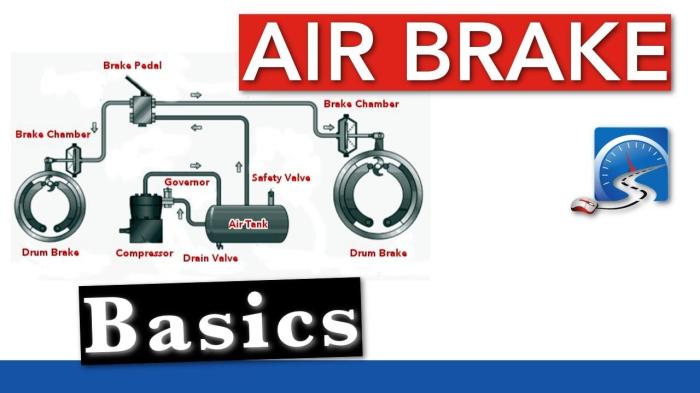

- Air Tanks:Found on the air tanks, which store compressed air for the vehicle’s braking system.

- Air Compressor:Located near the air compressor, which supplies air to the tanks.

- Air Lines:Positioned along the air lines that distribute air throughout the vehicle.

Types of Shut-Off Valves

Shut-off valves in CDLs come in various types, each with its own advantages and drawbacks.

The most common types of shut-off valves in CDLs include:

- Ball valves

- Gate valves

- Butterfly valves

Ball Valves

Ball valves utilize a spherical ball with a hole through its center to control the flow of fluids. When the valve is open, the hole aligns with the flow path, allowing fluid to pass through. When closed, the ball rotates 90 degrees, blocking the flow path.

Ball valves are known for their ease of operation, durability, and ability to handle a wide range of fluids. However, they may not be suitable for high-pressure applications due to the potential for leakage around the ball.

Gate Valves

Gate valves employ a sliding gate that moves up and down to control fluid flow. When open, the gate is lifted, allowing fluid to pass through. When closed, the gate descends, blocking the flow path.

Gate valves offer precise flow control and are suitable for high-pressure applications. However, they can be more difficult to operate than ball valves and may require more maintenance.

Butterfly Valves

Butterfly valves feature a circular disc that rotates within the valve body to control fluid flow. When open, the disc aligns with the flow path, allowing fluid to pass through. When closed, the disc rotates 90 degrees, blocking the flow path.

Butterfly valves are compact, lightweight, and relatively inexpensive. They are suitable for low-pressure applications where space is limited. However, they may not provide as precise flow control as ball or gate valves.

Operating Procedures

Shut-off valves in CDLs are critical for isolating and controlling the flow of fluids, including fuel, oil, and coolant. Operating these valves correctly is essential for safety and proper vehicle operation.

Before operating any shut-off valve, it is crucial to identify the valve’s location and purpose. This information can be found in the vehicle’s owner’s manual or by consulting with a qualified mechanic.

Safety Precautions

- Always wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Ensure the engine is turned off and the vehicle is in park or neutral before operating any shut-off valves.

- Never open or close a shut-off valve while the fluid is flowing through it.

- Be aware of the potential for hot or pressurized fluids when operating shut-off valves.

Operating Procedures

- Locate the desired shut-off valve and identify the direction of flow.

- Turn the valve handle or lever slowly and gently in the desired direction.

- Do not overtighten the valve, as this can damage the valve or its components.

- Once the valve is fully open or closed, check for leaks and ensure the valve is operating correctly.

Potential Hazards, Where are shut off valves cdl

- Opening a shut-off valve while the fluid is flowing can result in a sudden release of pressure, potentially causing injury or damage to the vehicle.

- Operating a shut-off valve improperly can lead to leaks, which can result in fluid loss or contamination.

- Overtightening a shut-off valve can damage the valve or its components, potentially leading to leaks or other issues.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting are crucial for ensuring the reliable operation of shut-off valves in CDLs. Regular inspections, testing, and servicing can help identify and resolve potential issues before they lead to failures.

Common Issues and Troubleshooting

Some common issues that may arise with shut-off valves include:

- Leaks:Leaks can occur due to worn or damaged seals, loose fittings, or corrosion. Inspect the valve for any signs of leakage and tighten or replace seals and fittings as needed.

- Sticking or Binding:Sticking or binding can be caused by dirt, debris, or corrosion buildup. Clean the valve and lubricate the moving parts to restore smooth operation.

- Incorrect Operation:Incorrect operation can result from improper installation or damage to the valve. Ensure that the valve is installed correctly and that the handle is operating smoothly.

- Failure to Close or Open:Failure to close or open can be due to a jammed handle, damaged valve seat, or a faulty actuator. Inspect the valve for any visible damage and replace or repair the affected components.

By addressing these common issues promptly, you can maintain the integrity and functionality of shut-off valves in CDLs, ensuring their reliable performance in critical situations.

Shut off valves are crucial for isolating and controlling water flow in commercial vehicles. Understanding their location is essential for drivers. If you’re curious about Ralph’s paint situation, check out this article: ralph has 3/4 gallon of paint . Back to shut off valves, their precise placement varies depending on the vehicle model, so it’s important to consult the manufacturer’s manual for specific instructions.

Regulatory Requirements

Regulatory requirements and standards play a crucial role in ensuring the safe and compliant operation of shut-off valves in CDLs. These regulations aim to minimize risks and protect personnel, the environment, and the general public.

Non-compliance with regulatory requirements can lead to severe consequences, including fines, penalties, license suspensions, and even criminal charges. It is imperative for CDL operators to be aware of and adhere to these regulations to ensure safety and legal compliance.

Federal Regulations

- Federal Motor Carrier Safety Regulations (FMCSRs): These regulations establish minimum safety standards for commercial motor vehicles, including CDLs. FMCSRs specifically address shut-off valves in §396.9, requiring them to be installed in readily accessible locations and capable of effectively stopping the flow of fuel in an emergency.

- Pipeline and Hazardous Materials Safety Administration (PHMSA): PHMSA regulates the transportation of hazardous materials, including flammable liquids. Its regulations require shut-off valves to be installed on cargo tanks used to transport flammable liquids.

Industry Standards

- National Fire Protection Association (NFPA): NFPA 30, Flammable and Combustible Liquids Code, provides guidance on the installation and maintenance of shut-off valves for flammable liquids.

- American Petroleum Institute (API): API Recommended Practice 1173, Recommended Practice for Electric Submersible Pumping Units, provides guidelines for the installation and operation of shut-off valves on electric submersible pumps used in oil and gas production.

Best Practices

To ensure the efficient and safe management of shut-off valves in CDLs, industry best practices recommend implementing a comprehensive approach that encompasses planning, maintenance, and risk mitigation.

By following these guidelines, organizations can optimize the performance of their CDLs, minimize potential risks, and maintain compliance with regulatory requirements.

Planning

- Develop a detailed plan that Artikels the location and function of each shut-off valve within the CDL.

- Identify and document potential risks associated with each valve and establish clear procedures for mitigating these risks.

- Train personnel on the operation, maintenance, and emergency response procedures for shut-off valves.

Maintenance

- Establish a regular maintenance schedule for all shut-off valves, including inspections, testing, and lubrication.

- Keep detailed maintenance records to track the condition and performance of each valve.

- Use specialized tools and equipment to ensure proper installation, repair, and testing of shut-off valves.

Risk Mitigation

- Conduct regular risk assessments to identify potential hazards associated with shut-off valves.

- Implement safety measures, such as lockout/tagout procedures, to prevent unauthorized access and accidental operation of valves.

- Establish emergency response plans that Artikel the steps to be taken in the event of a valve failure or leak.

FAQ Corner

What are the different types of shut-off valves used in CDLs?

The most common types of shut-off valves used in CDLs are ball valves, gate valves, and butterfly valves.

Where are shut-off valves typically located in CDLs?

Shut-off valves are typically located in the fuel tank, fuel lines, and engine compartment.

How do I operate a shut-off valve safely?

To operate a shut-off valve safely, first make sure that the valve is in the closed position. Then, slowly open the valve by turning the handle counterclockwise. Do not open the valve too quickly, as this could cause a fuel leak.