The rms current in a copy machine is – The root mean square (RMS) current in a copy machine is a crucial parameter that provides insights into the behavior of alternating currents within the device. Understanding RMS current is essential for optimizing copy machine design, operation, and troubleshooting.

This article delves into the significance of RMS current, methods for its measurement and calculation, factors influencing its value, implications for copy machine design and operation, and strategies for troubleshooting and mitigation.

1. Definition and Significance of RMS Current

The root mean square (RMS) current is a measure of the effective value of an alternating current (AC) over a period of time. It represents the equivalent value of a direct current (DC) that would produce the same amount of power in a resistive load.

Understanding RMS current is crucial for analyzing and designing electrical systems, including copy machines.

In a copy machine, the RMS current determines the amount of power drawn from the power supply and dissipated in the components. By understanding the RMS current, engineers can optimize the design of power circuits, minimize power losses, and ensure the efficient operation of the copy machine.

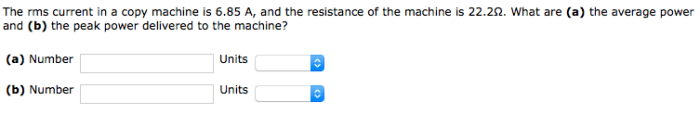

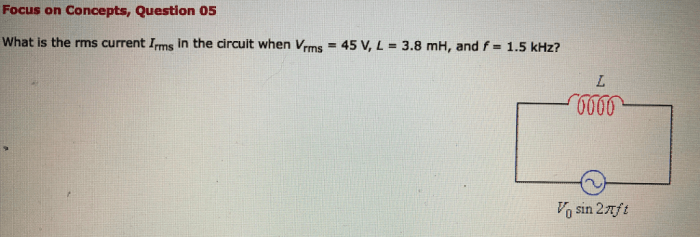

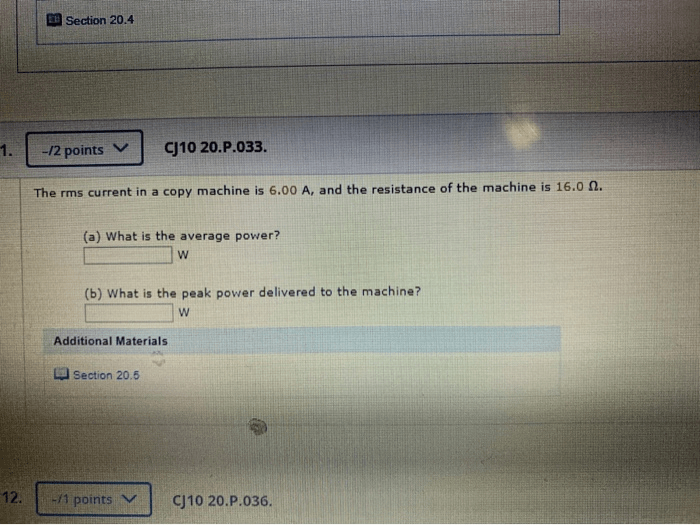

2. Measurement and Calculation of RMS Current

The RMS current in a copy machine can be measured using a clamp meter or an oscilloscope. The clamp meter measures the current flowing through a conductor without interrupting the circuit, while the oscilloscope displays the waveform of the current and allows for the calculation of RMS current from the waveform data.

The RMS current can be calculated using the following formula:

IRMS= √(1/T ∫ 0Ti 2(t) dt)

where:

- I RMSis the RMS current

- T is the period of the AC waveform

- i(t) is the instantaneous current

3. Factors Affecting RMS Current in a Copy Machine, The rms current in a copy machine is

The RMS current in a copy machine is influenced by several factors, including:

- Load Characteristics:The impedance of the load, including resistance, inductance, and capacitance, affects the current flow and thus the RMS current.

- Power Supply:The voltage and frequency of the power supply determine the maximum possible RMS current that can flow through the circuit.

- Copy Machine Operation:The operating modes and functions of the copy machine, such as scanning, printing, and copying, can vary the load characteristics and consequently the RMS current.

4. Implications for Copy Machine Design and Operation

Considerations of RMS current are crucial for the design and operation of copy machines:

- Power Efficiency:Minimizing RMS current reduces power losses and improves the overall efficiency of the copy machine.

- Component Longevity:Excessive RMS current can lead to overheating and premature failure of electrical components, including transformers, capacitors, and wires.

- Safety:High RMS currents can pose safety hazards due to the potential for electrical fires or shocks.

5. Troubleshooting and Mitigation Strategies

Common issues related to RMS current in copy machines include:

- Excessive RMS Current:Overloading, short circuits, or faulty components can lead to excessive RMS current. Troubleshooting involves identifying and addressing the underlying cause.

- Insufficient RMS Current:Insufficient power supply or undersized wiring can result in insufficient RMS current. Mitigation strategies include upgrading the power supply or replacing the wiring with a larger gauge.

To mitigate RMS current issues, the following strategies can be employed:

- Proper Load Sizing:Ensuring that the load is properly sized for the power supply and wiring prevents excessive RMS current.

- Regular Maintenance:Routine maintenance, including cleaning and inspection of electrical components, helps prevent faults that can lead to RMS current issues.

- Surge Protection:Surge protectors can prevent damage to electrical components caused by voltage spikes, which can contribute to RMS current problems.

Essential FAQs: The Rms Current In A Copy Machine Is

What is the significance of RMS current in copy machines?

RMS current provides a measure of the effective current flowing through the copy machine, which is crucial for understanding the power consumption and heating effects of the alternating current.

How is RMS current measured in copy machines?

RMS current can be measured using clamp meters or oscilloscopes that are capable of measuring AC currents. The measured RMS current value represents the equivalent DC current that would produce the same heating effect.

What factors influence the RMS current in copy machines?

Factors such as load characteristics, power supply voltage, and waveform harmonics can influence the RMS current in copy machines. Higher loads and higher power supply voltages generally result in higher RMS currents.

How does RMS current impact copy machine design and operation?

RMS current considerations are important for designing copy machines with efficient power usage and reliable operation. Managing RMS current helps prevent overheating, component damage, and premature failure.

What troubleshooting strategies can be employed for RMS current issues in copy machines?

Troubleshooting RMS current issues involves identifying the root cause, such as excessive load, power supply problems, or component malfunctions. Mitigation strategies may include load reduction, power supply adjustments, or component replacements.